In the high-stakes world of aviation maintenance, the safe transport of aircraft engines is paramount. Aircraft Engine Stands are specialized equipment designed to securely hold, transport, and store these powerful and delicate components. When it comes to relocating these multi-million-dollar assets, choosing the right airship engine stand rent solution can mean the difference between smooth operations and costly damage. Industry professionals seeking specific models like the PW1100 stand can find reliable options at https://stands.aero/product/pw1100/, ensuring proper support for these critical components.

Understanding Aircraft Engine Stands

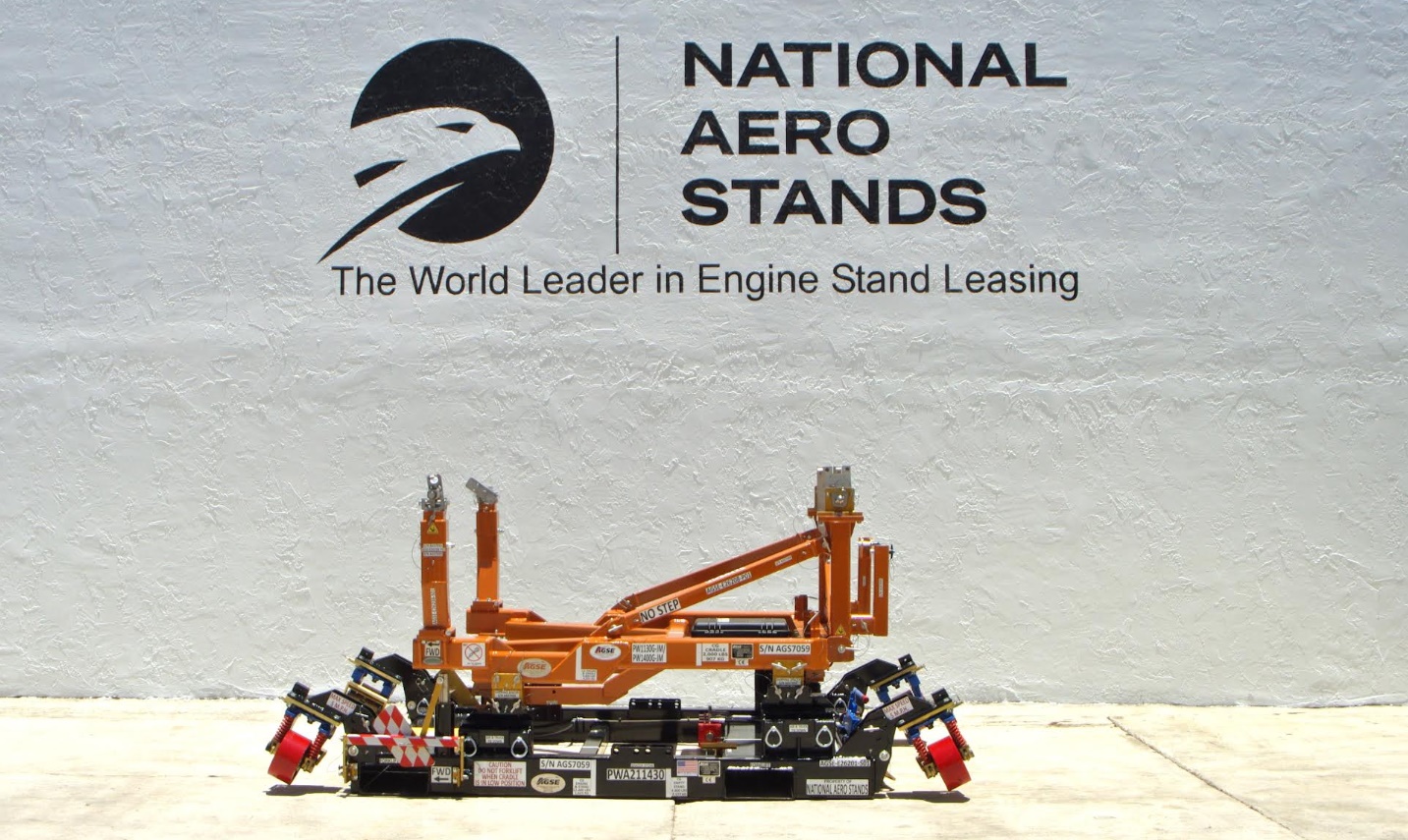

Aircraft engine stands serve as the backbone of engine maintenance and transportation operations. These specialized structures provide a secure framework for handling engines during removal, installation, storage, and transit. Modern stands are engineered to balance structural integrity with mobility, allowing maintenance crews to maneuver these massive components safely within hangars and across facilities. The evolution of these stands has transformed how MRO (Maintenance, Repair, and Overhaul) operations handle these critical assets, moving from basic frameworks to sophisticated systems with enhanced safety features.

Types of Engine Stands Available

Before selecting an engine stand, it’s essential to understand the various options on the market. The aviation industry utilizes several distinct types of stands, each designed for specific applications and engine models. These variations address different operational needs while maintaining core safety requirements.

Engine stand types commonly found in aviation facilities include:

- Universal transportation stands for multiple engine models

- Engine-specific OEM-certified stands

- Adjustable-height stands for maintenance flexibility

- Fixed-height stands for specific operational needs

- Modular systems with interchangeable components

Key Features for Damage-Free Transport

Ensuring the safety of aircraft engines during transport requires stands with specific design elements. These features collectively minimize the risk of damage while facilitating efficient handling.

Load Capacity and Structural Integrity

The primary consideration for any engine stand is its ability to safely support the engine’s weight. Modern aircraft engines can weigh several tons, making structural integrity non-negotiable. When evaluating stands for transport, operators must verify that:

- The stand’s load rating exceeds the engine’s weight by an appropriate safety margin

- All structural components show no signs of damage or fatigue

- Welding points and critical junctions maintain their integrity

- The base provides sufficient stability during movement and stationary periods

Mobility and Handling Mechanisms

Transporting engines requires stands with optimal mobility features. The best stands incorporate design elements that make movement smooth and controlled, reducing stress on both equipment and personnel.

Effective transport stands typically include:

- High-quality caster assemblies with locking mechanisms

- Ergonomic steering controls for precise positioning

- Low-profile designs that maintain a favorable center of gravity

- Shock-absorbing components to minimize vibration during transit

OEM Certification: Why It Matters

When selecting engine stands for transport, OEM certification represents a critical factor that impacts both safety and compliance. These certifications ensure the stand meets all requirements specified by the engine manufacturer.

Safety Standards and Compliance

OEM-certified stands undergo rigorous testing to verify their performance under various conditions. This certification process examines multiple aspects of the stand’s design and construction to ensure it will properly support the specific engine model throughout all handling phases.

The certification typically considers:

- Structural load testing under static and dynamic conditions

- Material quality and durability assessment

- Compatibility with engine mounting points and interfaces

- Stability during typical handling procedures

Long-term Cost Benefits

While OEM-certified stands often require a higher initial investment, they provide significant long-term advantages. These benefits extend beyond basic functionality to impact overall operational costs and efficiency.

Organizations that prioritize certified stands experience:

- Reduced risk of engine damage during handling

- Lower insurance premiums due to improved safety profiles

- Extended service life of the stand itself

- Simplified compliance with aviation authority requirements

Evaluating Durability for Long-Term Use

The durability of engine stands directly impacts their effectiveness and value over time. When assessing stands for potential acquisition, several factors help predict long-term performance.

Material Quality and Construction

The materials used in stand construction determine its resistance to wear, environmental factors, and physical stress. Superior stands utilize appropriate materials for different structural elements, balancing weight considerations with strength requirements.

Critical material considerations include:

- Corrosion-resistant metals and finishes for external components

- High-grade steel for primary load-bearing elements

- Precision machining of interface points to prevent wear

- Quality of hardware and fastening systems

Maintenance Requirements and Serviceability

Even the best stands require periodic maintenance to ensure continued safe operation. Stands designed with serviceability in mind offer advantages for organizations seeking to minimize downtime and maintenance costs.

Features that enhance serviceability include:

- Accessible lubrication points for moving components

- Modular design allowing replacement of individual parts

- Clear maintenance documentation and support

- Availability of replacement parts from manufacturers

Engine Stand Selection Guide

Selecting the appropriate engine stand involves careful consideration of numerous factors specific to your operation. This systematic approach helps ensure the chosen stand meets both immediate and long-term requirements.

Matching Stands to Engine Types

Different engine models require stands with specific dimensions, mounting interfaces, and load capacities. The aviation industry encompasses a wide range of engine types, from smaller turboprops to massive high-bypass turbofans.

When matching stands to engines, consider:

- Exact engine model compatibility verified by manufacturer documentation

- Weight capacity with appropriate safety margins

- Dimensional compatibility with handling areas and transport vehicles

- Specific attachment points and engine interface requirements

Operational Environment Considerations

The environment in which the stand will operate impacts selection decisions. Stands used primarily in controlled hangar environments face different demands than those regularly transported between facilities or exposed to outdoor conditions.

Environmental factors to evaluate include:

- Climate considerations for stands used in extreme temperatures

- Corrosion resistance for high-humidity or coastal operations

- Terrain challenges for stands used on uneven surfaces

- Space constraints in maintenance facilities

| Engine Type | Recommended Stand Features | Typical Weight Capacity | Notable Manufacturers |

|---|---|---|---|

| Narrow-body (CFM56, V2500) | Low-profile design, Enhanced mobility | 2,000-2,500 kg | AGSE, Frank Brown, Dedienne |

| Wide-body (GE90, Trent) | Reinforced structure, Hydraulic systems | 7,000-10,000 kg | Rhinestahl, Hydro, NextGen |

| Regional (PW1000G, CF34) | Compact footprint, Versatile positioning | 1,500-2,000 kg | DAE, Stanley, Champion |

| Military (F100, F110) | Security features, Ruggedized construction | 3,000-5,000 kg | AGSE, Stanley, GE |

Best Practices for Engine Stand Operation

Proper operation of engine stands is as important as selecting the right equipment. Following established best practices helps maximize safety while minimizing the risk of damage during transport and handling.

Loading and Securing Protocols

Safe engine mounting begins with proper preparation and adherence to established procedures. These protocols ensure the engine is correctly positioned and secured before any movement occurs.

Standard loading procedures involve:

- Verifying the stand’s condition and readiness before approach

- Using appropriate lifting equipment rated for the engine weight

- Following manufacturer-specified attachment sequences

- Confirming secure mounting with multiple verification points

Transport and Movement Guidelines

Once an engine is mounted, its movement requires careful attention to prevent damage from sudden impacts or excessive vibration. Proper transport techniques protect both the engine and surrounding equipment.

Key movement guidelines include:

- Maintaining slow, controlled speeds during transport

- Using dedicated pathways free of obstacles

- Employing minimum required personnel trained in movement procedures

- Avoiding sudden starts, stops, or direction changes

Recent Innovations in Engine Stand Technology

The field of engine stands continues to evolve, with manufacturers introducing new features to enhance safety, efficiency, and usability. These innovations address long-standing challenges while incorporating advanced materials and technologies.

Advanced Materials and Design

Modern stand manufacturing leverages materials science advancements to improve performance characteristics. These developments result in stands that are simultaneously lighter, stronger, and more durable than previous generations.

Recent material innovations include:

- High-strength aluminum alloys reducing overall weight

- Composite components in non-load-bearing applications

- Advanced coatings for enhanced corrosion protection

- Specialized polymers for vibration dampening

Digital Integration and Smart Features

The latest generation of engine stands incorporates digital technologies that provide enhanced monitoring and control capabilities. These features support more efficient operations while improving safety margins.

Emerging smart features include:

- Load sensors with digital readouts for weight verification

- RFID tracking for inventory management and maintenance scheduling

- Digital maintenance records accessible via QR codes

- Remote monitoring capabilities for stands in storage

Frequently Asked Questions

What is the primary purpose of an aircraft engine stand?

Aircraft engine stands serve multiple critical functions in aviation maintenance. They provide secure structural support for engines during removal and installation procedures, offer a stable platform for maintenance work, and enable safe transportation between facilities. These specialized tools are designed to protect the engine from damage while facilitating necessary handling throughout the maintenance process.

How often should engine stands be inspected?

Engine stands require regular inspection to ensure continued safe operation. Most manufacturers recommend a comprehensive inspection before each use, with detailed documentation of findings. Additionally, scheduled annual inspections by qualified personnel should evaluate all structural components, welds, and mechanical systems. These inspections typically include load testing and verification of critical safety features to identify any potential issues before they lead to failures.

Can one stand work for different engine types?

While universal stands exist, most engine types require model-specific stands designed for their particular dimensions and mounting points. Some modular systems offer adaptability across related engine families through interchangeable components. However, using a stand with an engine model it wasn’t designed for creates significant safety risks and potential for damage. Always verify compatibility through manufacturer documentation before attempting to use a stand with any engine model.

What certifications should I look for when purchasing engine stands?

When acquiring engine stands, several certifications indicate quality and compliance. The most important is OEM (Original Equipment Manufacturer) certification, confirming the stand meets all requirements specified by the engine manufacturer. Additionally, look for stands that comply with industry standards like those established by aviation authorities. Quality management certifications such as ISO 9001 suggest the manufacturer maintains consistent production standards, while specific material and welding certifications demonstrate attention to critical safety factors.

Conclusion

Selecting the right Aircraft Engine Stand represents a critical decision for aviation maintenance operations. These specialized tools not only facilitate efficient workflow but also protect valuable assets from damage during vulnerable transport phases. By prioritizing OEM certification, appropriate load capacity, and design features suited to specific operational needs, organizations can ensure their engine handling procedures maintain the highest safety standards. As stand technology continues to evolve, staying informed about innovations in materials, designs, and smart features allows maintenance teams to leverage the most effective solutions for their particular requirements.